Which Equipment Is Used For Mixing of Semi Solid On Large Scale?

Struggling to get a consistent mix for semi-solids on an industrial scale? This challenge can disrupt your production and impact product quality. The right equipment

Struggling to get a consistent mix for semi-solids on an industrial scale? This challenge can disrupt your production and impact product quality. The right equipment

Choosing the right materials for filter housings can make or break your project. Stainless steel offers unparalleled durability, but how does it truly impact your

Working with thick, sticky materials has always been a challenge in my 10+ years in the mixing industry. Traditional mixers simply can’t handle the demands

Struggling with inconsistent, high-viscosity battery slurries? Poor mixing can ruin battery performance and create costly waste, jeopardizing your production goals and market competitiveness. Double planetary

Battery manufacturers face enormous pressure to maintain consistency across thousands of production batches. One inconsistent electrode slurry can ruin entire battery cell production runs. Double

Battery slurry production fails without proper process control. Inconsistent mixing ruins electrode performance. Manufacturers struggle with complex multi-stage processes. Double planetary mixers provide complete process

Electrode mixing fails constantly. Dead zones ruin uniformity. Traditional mixers cannot handle high-viscosity materials properly. Double planetary mixers eliminate dead zones through dual-axis motion, handle

Creating perfect battery electrode slurry seems impossible. Uneven mixing ruins battery performance. Dead zones cause quality issues. Double planetary mixers solve these critical problems by

High-viscosity pharmaceutical formulations challenge conventional mixing equipment, leading to inconsistent batches, extended processing times, and regulatory compliance failures. Double planetary mixers excel in high-viscosity pharmaceutical

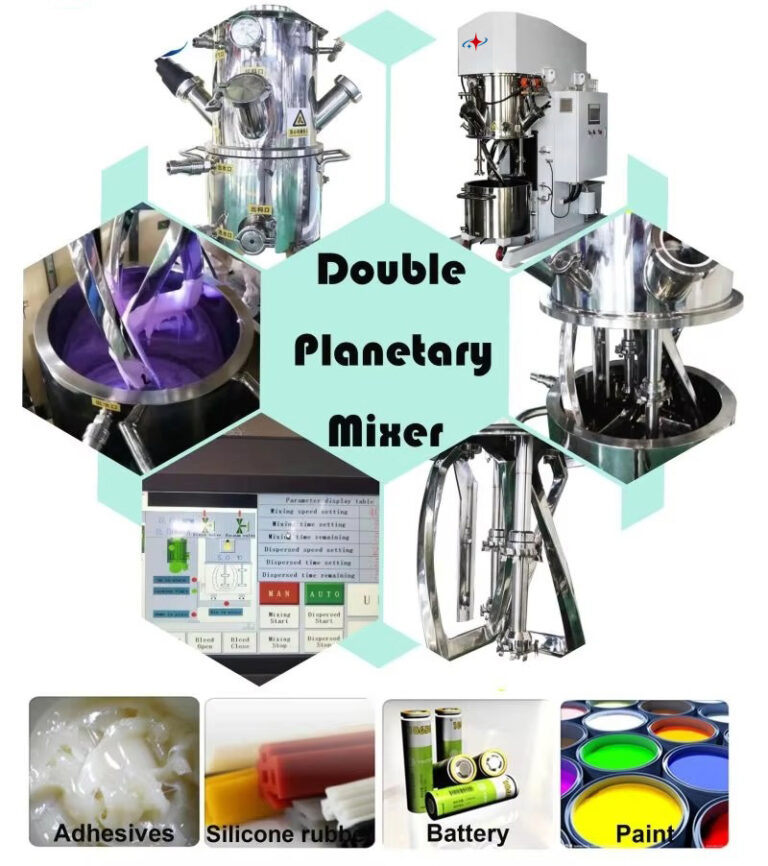

Choosing the wrong mixing equipment for high-viscosity materials leads to inconsistent product quality, extended processing times, and costly production failures. A double planetary mixer uses

Selecting the wrong planetary mixer can lead to inconsistent product quality, regulatory compliance issues, and costly production delays. Choose a planetary mixer based on your

Choosing the wrong mixer for biopharma production can cost millions in failed batches and regulatory compliance issues. Double planetary mixers excel in high-viscosity biopharmaceutical applications,

As Ronnie Guo, CTO of MIXERSTAR, I often get questions about planetary mixers. Many industries need the right type to handle their mixing tasks efficiently.

As Ronnie Guo, CTO of MIXERSTAR, I’ve worked with various mixing machines for over a decade. They each solve unique problems in industries like chemicals

As Ronnie Guo, CTO of MIXERSTAR, I’ve seen how planetary mixers transform industries with their precise mixing. They solve common problems like uneven blends and

What is a Lab Vacuum Mixer? Lab Vacuum Mixer FAQ With over 15 years of experience manufacturing Lab Vacuum Mixers, we understand that precision and

Professional Industrial Planetary Mixer

Typically replies within minutes

Hello My Friend, would like know more about related to Professional Industrial Planetary Mixer https://mixerstar.com/?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us